Bài viết

YARN-DYED LINEN AND PIECE-DYED LINEN: WHAT IS THE DIFFERENCE?

In the textile industry, the dyeing process plays an important role in determining the quality and color of the final product. Two of the most popular dyeing methods today are piece dyeing and yarn dyeing. Each method has its own characteristics to suit the different needs of the fashion industry. In this article, let’s learn more about the differences between these two dyeing methods with Linen Vietnam!

Table of Contents

What is piece-dyed linen?

Piece-dyeing is a process in which the entire piece of fabric is dyed after it has been woven or knitted. The fabric, usually in large rolls, is dipped into a dye bath to absorb the color. This process helps the color cover the entire surface of the fabric.

This method became popular in the 18th and 19th centuries, when the textile industry grew rapidly and the need to produce large quantities of fabric with consistent colors increased.

What is yarn-dyed linen?

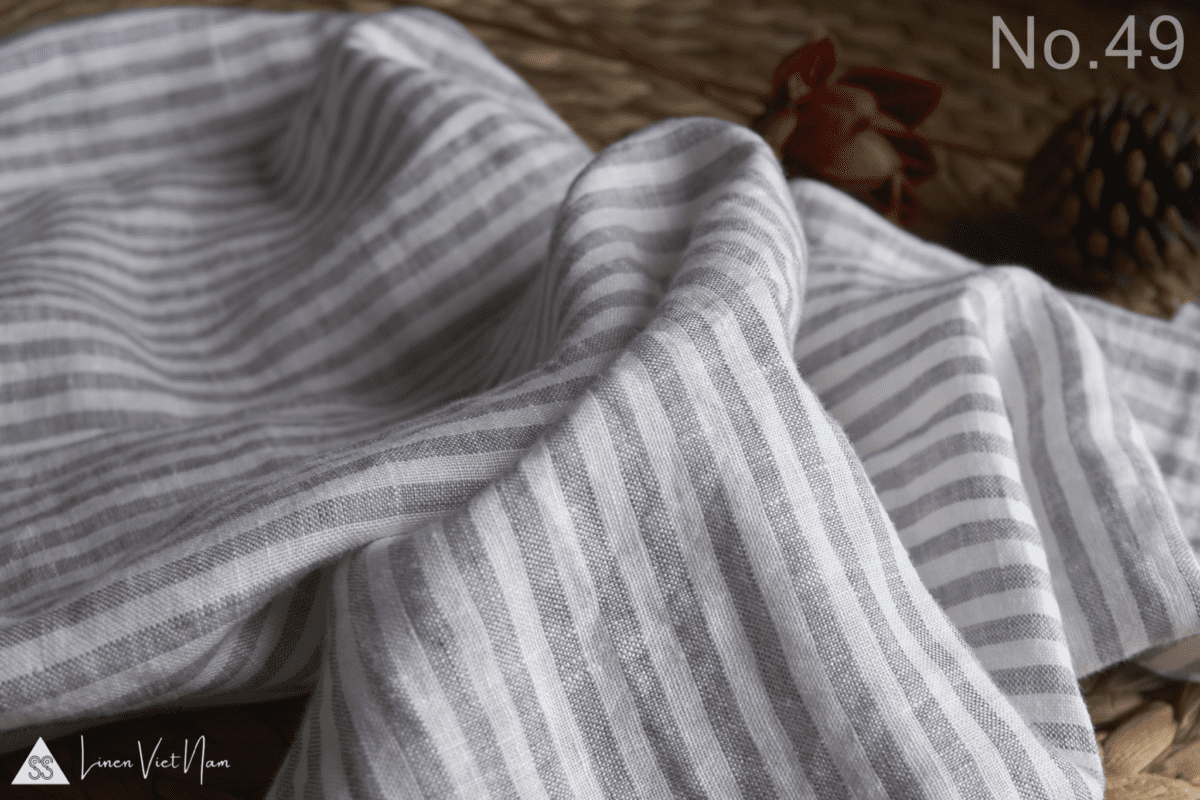

Unlike the piece-dyeing method, yarn-dyeing is the process of dyeing individual fibers before they are woven or knitted into fabric. This technique is often used to create patterns such as checks, patterns or stripes. Because the fibers are dyed before they are woven, the colors tend to be more durable and less prone to fading than piece-dyed fabrics.

Advantages of piece-dyed linen

One of the biggest benefits of piece-dyed linen is its flexibility in production. Because the linen fabric is dyed after it has been woven, it can be quickly adapted to specific color requirements without having to stock different types of dyed yarn. This reduces inventory costs and facilitates the production of large quantities of uniform colors.

This method is also particularly suitable for products that require uniform color across the entire surface, such as bed linen, curtains, or fashion clothing with basic colors.

Advantages of yarn-dyed linen

One of the biggest benefits of yarn-dyed linen is their high color fastness. Because each yarn is carefully dyed before being woven or knitted, yarn-dyed products are less likely to fade, maintaining their brightness longer through many washes. This method is also ideal for creating complex patterns and motifs, adding aesthetics and luxury to the product. Thanks to its good color retention and design flexibility, yarn-dyed is the perfect choice for products that require high aesthetics and long-term use.

The difference depends on how you choose

The difference between these two fabric types ultimately depends on your specific needs and preferences. When deciding which fabric to choose, it’s essential to think about the end purpose of the material. If you need a product with a solid, uniform color, and are cost-effective, whole-piece dyed linen is the ideal choice. On the contrary, if you are pursuing designs with complex patterns and want to ensure high color fastness, yarn-dyed linen will be more suitable.

Currently, Linen Vietnam provides linen products dyed by both yarn-dyed and piece-dyeing methods with a variety of weights from 165GSM, 175GSM, 177GSM and 300GSM to meet the diverse needs of the market.

If you want to experience linen with excellent quality, do not hesitate to inbox the Linen Vietnam fanpage for detailed advice!