Uncategorized

The Artisanal Process of Linen Fabric Production Unveiled

In the realm of textile craftsmanship, few materials carry the allure and time-honored tradition of linen. Renowned for its natural elegance, breathability, and durability, linen fabric stands as a testament to the meticulous artistry of its production process. Delving into the intricate journey from flax cultivation to the weaving of threads, let's unravel the enchanting narrative of crafting linen through time-honored hand techniques.

Cultivation of Flax

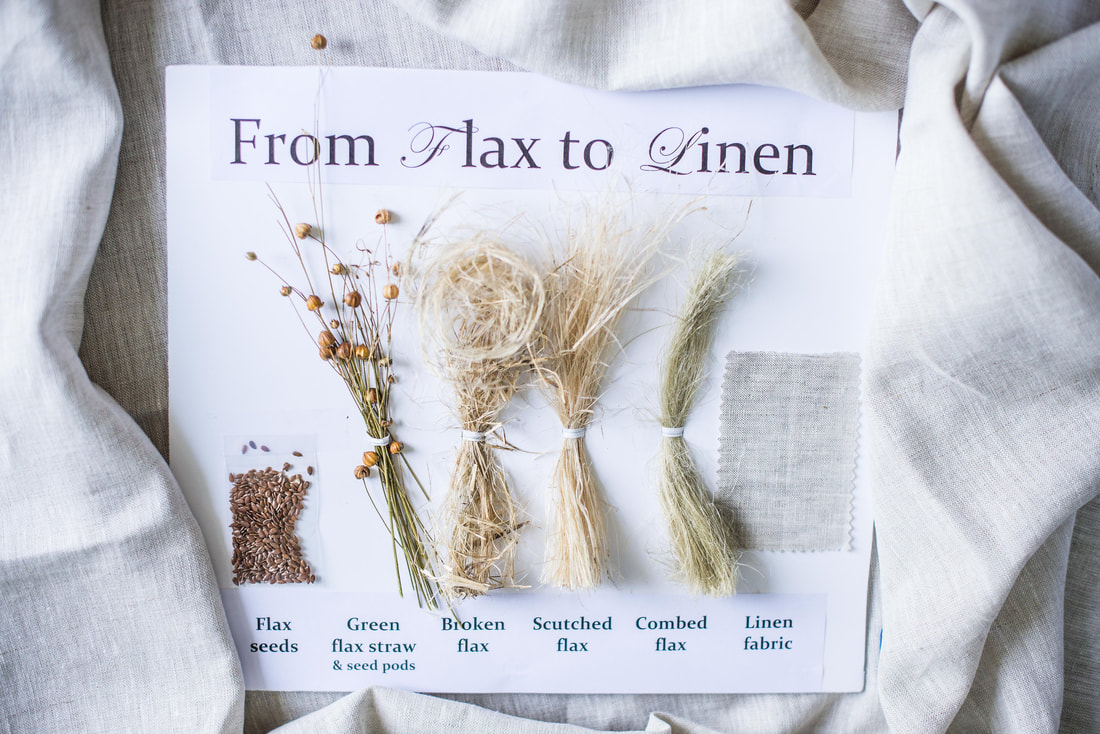

The journey of linen begins with the cultivation of flax, a resilient plant known for its slender stalks and delicate blue flowers. Cultivated primarily in temperate climates, flax requires meticulous attention and care throughout its growth cycle. Farmers employ traditional methods, nurturing the flax from seedling to maturity, ensuring optimal fiber quality.

Harvesting and Retting

Once the flax reaches maturity, it undergoes the delicate process of harvesting. Hand tools are employed to carefully uproot the plants, preserving the integrity of the fibers. Subsequently, the harvested flax undergoes retting, a crucial step where the stalks are exposed to moisture, facilitating the separation of fibers from the woody core. This age-old technique, often carried out in natural bodies of water or under controlled conditions, ensures the fibers achieve the desired suppleness and strength.

Breaking and Scutching

Following retting, the flax undergoes breaking and scutching, where the fibers are further separated from the straw and impurities. Skilled artisans utilize traditional tools such as scutching knives and wooden beaters to meticulously refine the fibers, discarding any remnants of the woody core. This manual process requires precision and expertise, ensuring the fibers retain their intrinsic qualities.

Hackling and Spinning

The refined flax fibers, now known as flaxen, are subjected to hackling, a meticulous combing process that aligns the fibers and removes any remaining impurities. This step is crucial in enhancing the fineness and uniformity of the fibers, preparing them for the spinning process. With deft hands, artisans spin the flaxen into fine threads, employing traditional spinning wheels or hand-operated devices. This stage demands patience and skill, as artisans strive to achieve consistent yarns prized for their strength and luster.

Weaving and Finishing

Finally, the spun linen yarns are ready for the loom, where skilled weavers bring them to life through intricate patterns and textures. Whether handloomed or mechanized, the weaving process requires meticulous attention to detail, as each thread is meticulously interlaced to form the fabric’s structure. Once woven, the linen fabric undergoes finishing treatments, which may include washing, bleaching, or dyeing, further enhancing its softness and aesthetic appeal.

Embracing Tradition in a Modern World

While advancements in technology have revolutionized textile production, the art of crafting linen fabric remains deeply rooted in tradition and artisanal skill. Each step of the process honors centuries-old techniques passed down through generations, resulting in exquisite fabrics celebrated for their timeless beauty and sustainability.

In conclusion, the journey of producing linen fabric epitomizes the harmonious blend of nature, craftsmanship, and heritage. From the humble flax seed to the intricately woven fabric, every stage of the process embodies a reverence for tradition and a commitment to excellence. As we embrace the allure of linen, let us cherish the enduring legacy of artisanal craftsmanship that defines this exquisite textile.